Umshini Wokupakisha we-TMZP100 Flow Wrapper

Incazelo emfushane:

Lo mshini wokupakisha umcamelo ogelezayo uyasebenza ekupakisheni izinto ezijwayelekile ezahlukahlukene eziqinile, njengamabhisikidi, amakhukhi, ama-ice pop, ikhekhe leqhwa, ushokoledi, uswidi, umuthi, insipho yehhotela, izinto zansuku zonke, izingxenye zehadiwe nokunye.

In-feed ingxenye kungenziwa egcizelele ngokuvumelana nezidingo zangempela.

Ingakwazi ukuxhumana nemishini ekhuphuka nomfula uma kudingeka.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Imingcele Yezobuchwepheshe

| Imodeli | I-TMZP-100 |

| Isivinini | 35~220 ama-pcs/min |

| Usayizi wesikhwama | (L)65- 200mm(W)30-90mm(H)5-30mm |

| Ububanzi befilimu | 65-220 mm |

| Indaba Yefilimu | I-OPP/CPP PT/PE KOP/CPP ALU-FOIL |

| Ubukhulu | (L)4000mmX(W)850mmX(H)1600mm |

| Amandla okushisa | 2.4kW |

| Amandla emoto | 0.6kW |

| Amandla aphelele | 3kw |

| Isisindo sisonke | 550kg |

Umshini Wokupakisha Ovundlile we-TMZP-100 onesivinini esikhulu ne-CE

1.Isingeniso somkhiqizo

Lo mshini wokugoqa ogelezayo uyimodeli yokuqala eyasungulwa enezikhwama ezingama-220 ngejubane elizinzile ngomzuzu, oklama imikhiqizo emincane, njengekhekhe, ibhisikidi, izicubu, izingxenye zehardware.

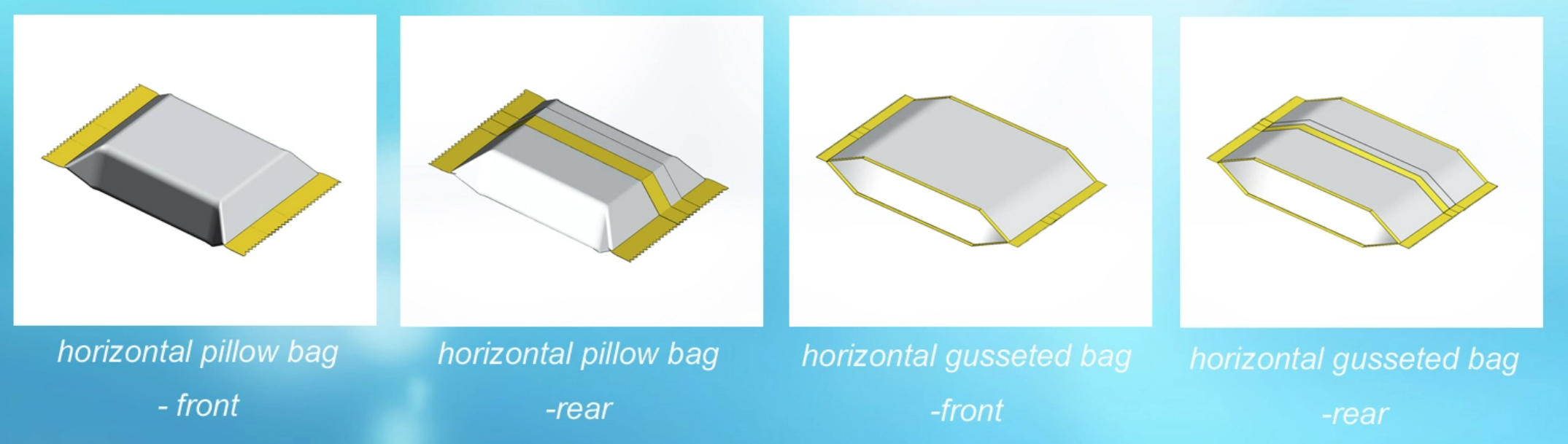

Imishini ezenzakalelayo yemikhiqizo ephezulu.Ukupakisha okuvundlile kusetshenziswa ikhoyili yefilimu eyodwa enezinsimbi ezintathu: ama-cross-weldings amabili kanye ne-longitudinal welding eyodwa.Lolu hlobo lomshini wokupakisha luqondiswe ezimakethe zokudla nezingezona zokudla.

2. Izimpawu Nezici Zesakhiwo

(1) Thola ngokuzenzakalelayo futhi usethe ubude besikhwama ngaphandle kokusetha okwenziwa ngesandla esikrinini sokuthinta semishini yokupakisha

(2) Isakhiwo somshini esilula esinamasondo aguquguqukayo, kulula ukusinakekela noma ukushintsha indawo.Iqinisekisa ubude bempilo ende kanye nenhlanzeko.

(3) I-chip eyodwa yesekethe yokulawula eyinhloko eyakhiwe inkampani yethu.Isikrini sedijithali nokulawula kwe-transducer kuqinisekisa ukusebenza kahle

(4) Ukulawula okuphindwe kabili kwe-transducer nge-speed shiftless step kanye nokulungiswa okubanzi, Kungahambisana kahle nenqubo yokusebenza yangaphambili yomugqa wokukhiqiza;

(5)Umtshina ozwela kakhulu ngokuzenzakalelayo futhi uqapha yonke inqubo yokupakisha.

(6) Ukulawulwa kwezinga lokushisa okuzimele kuqinisekisa amaphakheji amahle futhi aqinile okuvalwa.

(7) Ifanele inhlobonhlobo yezinto zokupakisha eziguquguqukayo, usayizi wokupakisha kanye nemikhiqizo.

(8)Idivayisi ozikhethela yona: Iphrinta yosuku, idivayisi yokushaja komoya nama-servo motors

(9)Umshini onomklamo ohlangene, olungele ukukhiqizwa kwezinga elincane.

(10) Ukwakhiwa kwedizayini yeCantilever ukuze kuthuthukiswe ukuhlanzeka komshini nokuhlanza.

(11)2.5 m ubude be-conveyor yempahla yokupakisha.

(12)Isibambi se-reel esiphezulu esinomshini wokuziqinisa wesondo ogxile kuwo kanye nesistimu yokubhuleka.

(13)Amapheya amathathu amarola okudonsa ifilimu nama-longitudinal seals.

(14)Ikhanda elivala umhlathi elizungezayo elinokuguquguquka okukhulu.

(15)iphimbo lokungena elilungisekayo lemikhiqizo eyahlukene

(16)Ibhokisi legiya likamakhenikha ukulungisa ubude besikhwama

(17)I-shaft enamazinyo ezocushwa ngokuya ngobude bomkhiqizo

(18)Amakhava okuphepha anamaswishi amancane okuphepha

(19)54 mm ibhande lokuphakela ngaphandle/ibhande eliqediwe lempahla yokupakisha

(20) Ukulawula izinga lokushisa okuhlakaniphile, isibonisi esinembile, kulula ukusibeka, izinga lokushisa elinembile

3. Idivayisi Engazikhethela Yezinto Zokupakisha

(1)"Awukho umkhiqizo - Awukho isikhwama".

(2)Imitha eyengeziwe yokuthutha impahla.

(3)I-Photocell yefilimu ephrintiwe emaphakathi.

(4)Isibambi se-reel kabili.

(5)Amaphrinta ekhodi yedethi.

(6)Ithuluzi lokushutha.

(7)Imimese yokusika iZigzag.

4. Imininingwane Yomshini Wokupakisha Isingeniso:

Umnikazi we-A.Spool/ Ukwesekwa kwangempela kwefilimu mayelana nomshini wokupakisha

Umnikazi we-spool uyazicabangela yena futhi uvumela ukushintshwa kwe-spool yefilimu kalula

Izibambi ze-spool ezizenzakalelayo eziphindwe kabili ziyatholakala njengenketho yokwengeza uma isifakeli selebula singafakiwe

Isondo le-B.Seal mayelana nomshini wokupakisha

Uhlelo lokumelana nogesi lusiza ukugwema ukushiswa kwefilimu, ngisho nalapho umshini ungasebenzi

Uhlelo lulawulwa ukulawulwa kwezinga lokushisa kwedijithali nge-HMI yesikrini esikabili ukulungisa ama-asynchronies futhi kunciphisa ukungezwani ku-+/-2°C.

Uhlelo lokumelana nama-roller lwenziwa lusebenze ngokudluliselwa kwesimo esiqinile

Ukulawulwa kwezinga lokushisa kunezimpawu eziningi ze-alamu zokuxwayisa opharetha uma kuphakama izinkinga

Amaphuzu okugcoba aphakathi nendawo ukuze anakekeleke kalula

Umhubhe owakhayo uyalungiseka emhlabeni wonke ngobude nobubanzi

C.Head-cutter mayelana nomshini wokupakisha

Inkinobho kagesi esebenziseka kalula ku-HMI isetshenziselwa ukubeka umkhiqizo ngesisiki sekhanda

Ukulawula izinga lokushisa kufakwe amasignali amaningana e-alamu

I-blade yokusika ilungiseka ngokugcwele

Amaphuzu okugcoba aphakathi nendawo ukuze anakekeleke kalula

Isakhiwo seqembu siyinsimbi eboshwe futhi izindawo zokushisa zihlukaniswa ngomshini ukuze kuvunyelwe ukusabalalisa ukushisa okuhle kakhulu.

I-pressure dampener ishintshwa yiziphethu ezimbili

Lo mshini uhlome ngezinto zokuphepha ukuze uvikele ukulimaza oomakhenikha.Ukuzwela kungalungiswa ngokuya ngomkhiqizo

Izilawuli zivumela ububanzi obuguquguqukayo nobude bemikhiqizo

D.IPHEPHA LOKULAWULA

I-E.IN-FEED CONVEYOR

I-in-feed conveyor inobude obungamamitha angu-2.5 futhi ineziqondiso ezisemaceleni zensimbi engagqwali ezingavulwa futhi zihlanzwe kalula.I-conveyor engaphakathi kokuphakelayo ozikhethela yona engu-1000-3000 mm nayo iyatholakala.

Amapusha akhiphekayo enziwe ngepulasitiki yekhwalithi ephezulu futhi agunyazwe ukusetshenziswa nemikhiqizo yokudla

Umkhiqizo uthuthwa ama-Teflon mats ukugwema umonakalo

Imbobo engezansi ye-conveyor e-in-feed incike ukuze inikeze ukufinyelela okulula kokuhlanza

Bonisa