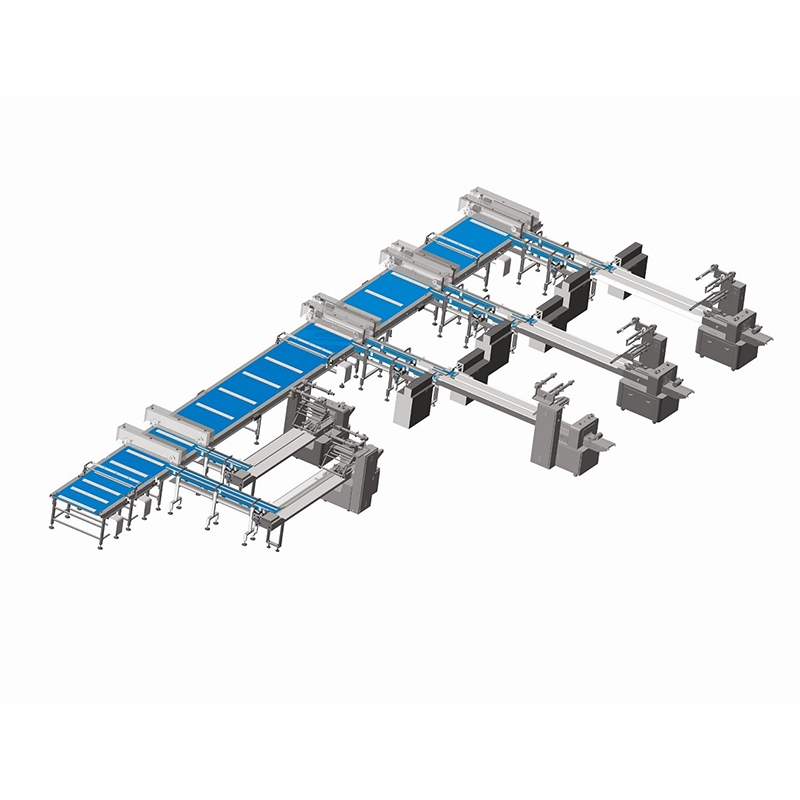

I-Automatic Wafer Packing Line Uhlobo lwe-L

Incazelo emfushane:

Lo mugqa wokupakisha we-wafter othomathikhi uyasebenza ku-wafer neminye imikhiqizo efanayo yokusika enomthamo omkhulu, kodwa ihlelekile futhi isesimweni esivamile. Ixazulula izinkinga zendabuko ezifana namabanga aseduze phakathi kwemikhiqizo, kunzima ukujika, akulula ukuhlela emigqeni, njll ukuze kuzuzwe ifomu lokupakisha elilodwa noma amaningi.

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

Imininingwane Yomkhiqizo

Lolu hlelo lokupakisha oluzenzakalelayo lwenzelwe imikhiqizo enethreyi noma ibhokisi, futhi lo mugqa wokupakisha ungalayisha ngokuzenzakalelayo ithreyi nokupakisha ngaphandle kokusebenza ngesandla.

Isisebenzi esisodwa singasebenzisa imigqa emibili, okusiza ukonga izindleko zabasebenzi kumakhasimende.

Lo mugqa wokuphakelayo kanye nokupakisha kufakwe i-deoxidizer noma i-ejenti ye-deoxidizing pad feeder, iyunithi yokumunca ithreyi, iyunithi yokulayisha ezenzakalelayo yethreyi nomshini wokupakisha.

Ijubane lokupakisha le-tray yokulayisha kanye nomugqa wokupakisha yizikhwama eziyi-100-120 ngomzuzu.

1. Ukwethulwa Komkhiqizo Wezisetshenziswa Zokusonga Ezivundlile Ezizenzakalelayo ze-Swiss Roll

Lolu hlelo lokupakisha lwe-wafer luwuhlelo olunemisebenzi eminingi, olungapakisha iwafa eyodwa kanye namawafa amaningi. Siklame lonke uhlelo lokupakisha ngokwesakhiwo sakho kanye nophenyo. Isivinini esiphezulu singafika ku-250 izikhwama/ngomzuzu. Ijubane lephakethe lomndeni lincike kusayizi.

2. Umsebenzi Oyinhloko Womshini Wokupakisha Ukudla we-Wafer

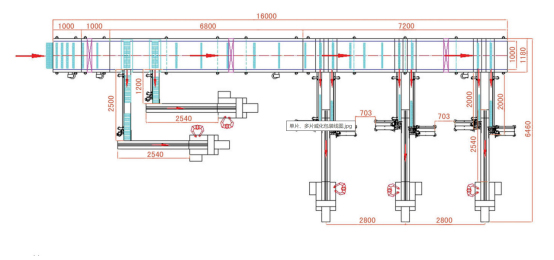

Ulayini wokupakisha wama-wafer uqukethe isilawuli sebanga, isidluliseli esihlehlayo, iyunithi yokuhlela ngokuzenzakalelayo, nomshini wokupakisha. Lolu hlelo luzosiza ukuvumelanisa okuzenzakalelayo kwe-wafer, ukuqhelelana, ukusabalalisa, nokuletha kuyunithi yokuhlunga nokuqeda ukupakisha ukuze kugcinwe ukukhiqizwa okuqhubekayo nokuhlelekile okunodoti ophansi kanye nephakheji elihle. Isifutho sotshwala kanye nokushaja umoya kuyakhethwa.

Isivinini sokupakisha somugqa owodwa singafinyelela izikhwama ezingama-80-220/min.

Lonke uhlelo lokupakisha lwamukela i-220V, 50HZ, isigaba esisodwa. Amandla Aphelele angu-26KW

Uhlelo lokupakisha ukudla lungasebenzisa amamodeli okupakisha ahlukene ngokuya ngemibuzo yomkhiqizo wamakhasimende.

3. Inzuzo Yesistimu Yokupakisha Ukudla Okuzenzakalelayo Yebhisikidi Yesinkwa

Ulayini wokupakisha ovundlile ofakwe idivayisi yokuqondanisa ngokuzenzakalela nekhava evikelayo. Idivayisi yokulungisa ngokuzenzakalela ingokuzithandela.

Isakhiwo esenziwe lula, ukusebenza okulula, ukuhlanzwa okulula, nokugcinwa kahle. Ukulungiswa okulula kwemikhiqizo ehlukene noma izilungiselelo zepharamitha.

Uhlelo Lokulawula lisebenzisa i-elekthronikhi yekhwalithi ephezulu, i-PLC ehlakaniphile, isikrini sokuthinta, ne-HMI enhle, isebenza kalula futhi kalula.

Ulayini wokupakisha ogelezayo ufakwe ibhande lejubane elihlukile ukuze uhlele izinkwa noma amakhekhe ukuze kuqinisekiswe isivinini esikhulu esizinzile futhi sithole ngokunembile.

Umshini ozenzakalelayo wokupakisha ukudla kanye nesistimu zisebenzisa insimbi engagqwali kanye ne-Nylon baffle, kulula ukuyisebenzisa nokuhlanza.

Ibhande le-PU lingakhishwa ngaphandle kwamathuluzi emzuzwini ongu-1 futhi lifakwe i-hopper ukuze lithole imfucuza yomkhiqizo, okulula ukuyihlanza nokuyinakekela.

Isakhiwo semishini yokudla silula kakhulu, sisebenza kalula, silungele ukuhlanzwa nokugcinwa. Ukulungiswa okulula kwemikhiqizo ehlukene noma izilungiselelo zepharamitha.

Isistimu yokulawula yemishini yokupakisha yefilimu yepulasitiki isebenzisa i-elekthronikhi yekhwalithi ephezulu, i-PLC ehlakaniphile, isikrini sokuthinta, ne-HMI enhle, isebenza kalula futhi kalula.

Sizokwengeza i-conveyor engu-90-degree turning conveyor noma 180-degree turning conveyor ohlelweni lokupakisha ngokuvumelana nesakhiwo sefekthri yamakhasimende noma isikhala.

Ifakwe umtshina wamamitha kanye nesihloli sesisindo, esingaxhuma ngokuzenzakalelayo nohlelo lokupakisha lokugeleza.

Umshini wokupakisha ukudla ozenzakalelayo we-wafer ofakwe idivayisi yokuqondisa ngokuzenzakalela kanye nedivayisi yokulungisa okuzenzakalelayo yebhande uyazikhethela.

Ulayini wokupakisha ungaqondanisa ama-wafers (imikhiqizo) futhi ulethe kuyunithi yokuhlunga ngokuhlelekile ukuze kuqinisekiswe isivinini esikhulu ngokuzinzile futhi siwathole ngokunembile.

Ibhande le-PU lomshini wokupakisha lingakhishwa ngaphandle kwamathuluzi futhi lifakwe i-hopper ukuze lithole imfucuza yomkhiqizo, okulula ukuyihlanza nokuyilungisa.

Isakhiwo esenziwe lula, ukusebenza okulula, ukuhlanzwa okulula nokugcinwa. Ukulungiswa okulula kwemikhiqizo ehlukene noma izilungiselelo zepharamitha.

Uhlelo lokulawula umugqa we-wafer lusebenzisa i-elekthronikhi yekhwalithi ephezulu, i-PLC ehlakaniphile, isikrini sokuthinta, ne-HMI enhle, esebenza kalula futhi kalula.

Ibhande le-PU lomugqa wokupakisha we-wafer lingasebenzisa ubufakazi obunamathelayo obunombala omhlophe ngokuzikhethela.

4. Ukusetshenziswa Kwemishini Yokupakisha Okuzenzakalelayo

Kusebenza ukupakisha ukudla okukhishwe kanye nomunye umkhiqizo ojwayelekile, owenziwe ngemishini yokusika. Ixhunywe nolayini wokukhiqiza wangaphambilini ngokuphakelayo okuzenzakalelayo noma okuphakelayo okwenziwa ngesandla.

5. Amasampula Okupakisha

6. Ukudweba kwe-Automatic Packaging Solution

7. Imininingwane Yesistimu Yokupakisha.

(1) Isilawuli sebanga

Umsebenzi oyinhloko wesilawuli sebanga ukudonsa ibanga lomkhiqizo noma uwagcine emigqeni.

(2) Ukusabalalisa umshini wokuthungatha

Lesi sithumeli esisabalalisa isixazululo sokupakisha sisetshenziselwa ukuletha imikhiqizo emigqeni ehlukene yokupakisha. Ubude balezi zingxenye buncike emandleni okukhiqiza amakhasimende noma ukwakheka kwefekthri.

(3) I-Direction pusher

I-direction pusher ivamise ukusebenzisa uhlelo lokupakisha lwe-wafer kuphela, olusiza ukushintsha isiqondiso se-wafer futhi ilethe emshinini wokupakisha ohlukile.

(4) Ibhande lokugcina

Umsebenzi oyinhloko webhande lokugcina ukugcina lawo mawafa nokusiza ukuletha emshinini wokupakisha, ukuqedela ukupakisha.

(5) I-Servo pusher

Isingeniso: Le servo pusher isebenzisa kuphela ulayini wokupakisha wamawafa omndeni. Ngamagama ahlelekile, uma udinga ama-6pcs esikhwameni ngasinye (2layer kanye nongqimba ngalunye izingcezu ezi-3), khona-ke le ngxenye idinga uku-oda. Uma nje udinga ukupakisha i-wafer eyodwa, asikho isidingo salezi zingxenye.

Umsebenzi: Umsebenzi oyinhloko ukusunduza i-wafer yeqembu ku-conveyor ye-infeed, bese upakisha.

(6)Iyunithi yokuhlunga

Iyunithi yokuhlunga yesingeniso sesistimu yokupakisha:

Izingxenye zeyunithi yokuhlunga ziqukethe amabhande ama-2 okuthutha kanye nezinzwa ezingu-5-6.

Umsebenzi weyunithi yokuhlunga:

Umsebenzi oyinhloko wale yunithi yokuhlunga ukulawula isivinini sokuphakelwa komkhiqizo, ukuyibeka, bese uyixhuma ngomshini wokupakisha ngokuzenzakalelayo. Uma ithole umkhiqizo kakhulu, ijubane lokudla lizohamba kancane, uma ukuntuleka komkhiqizo, khona-ke isivinini sokudla sizokhuluma maduzane.

Inzuzo yeyunithi yokuhlunga:

Ukunciphisa ukusebenza komuntu futhi uqiniseke ukuthi umshini wokupakisha usebenza ngesivinini esizinzile onokulahlwa kwemikhiqizo embalwa.